水泥厂加工熟料的设备,水泥生产工艺流程

2021-01-07T13:01:00+00:00

水泥生产线设备工艺流程三维仿真动画演示 知乎

Web水泥生产线设备工艺流程三维仿真动画演示 左右大叔 数字视觉技术和3D可视化数字孪生解决方案 14 人 赞同了该文章 水泥生产线(水泥厂设备)是生产水泥的一系列设备组成 Web生产及能耗情况 水泥厂产品质量及能耗量与生产质量息息相关,应用图扑 ht 强大的渲染引擎,将熟料、水泥的综合电耗、标煤耗、吨熟料发电量以及生料、熟料、水泥合格率以图 图扑软件 数字孪生智慧水泥工厂 知乎

水泥生产工艺流程(主要七个步骤) 环问问

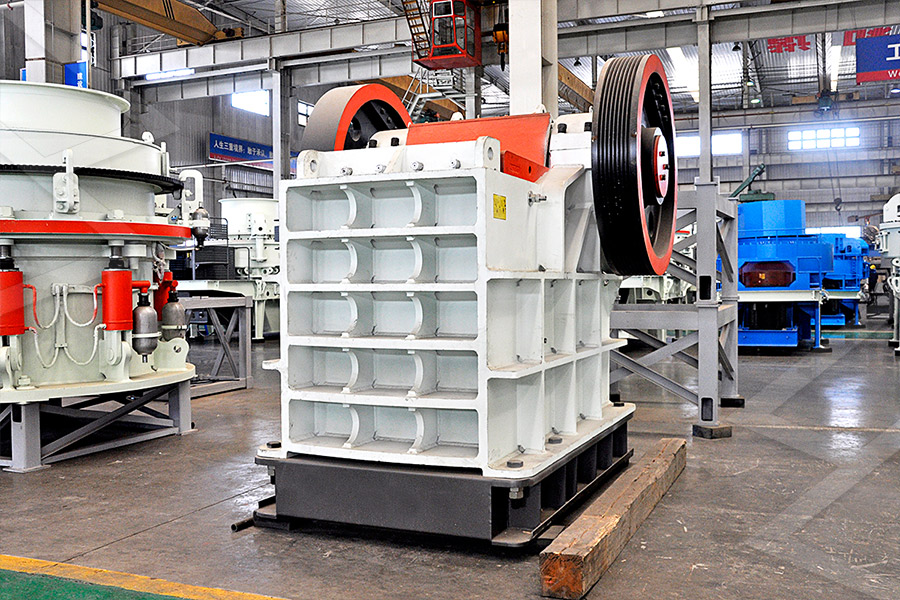

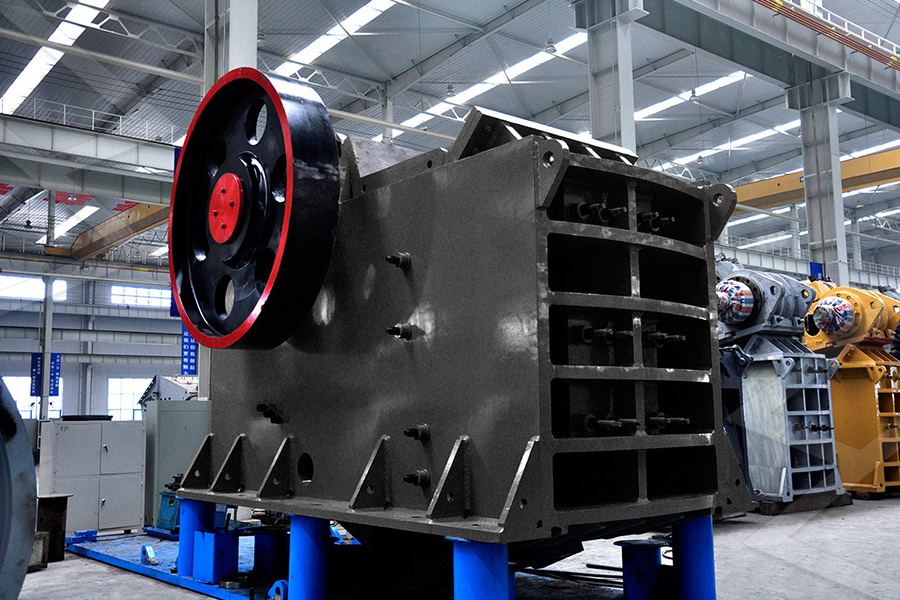

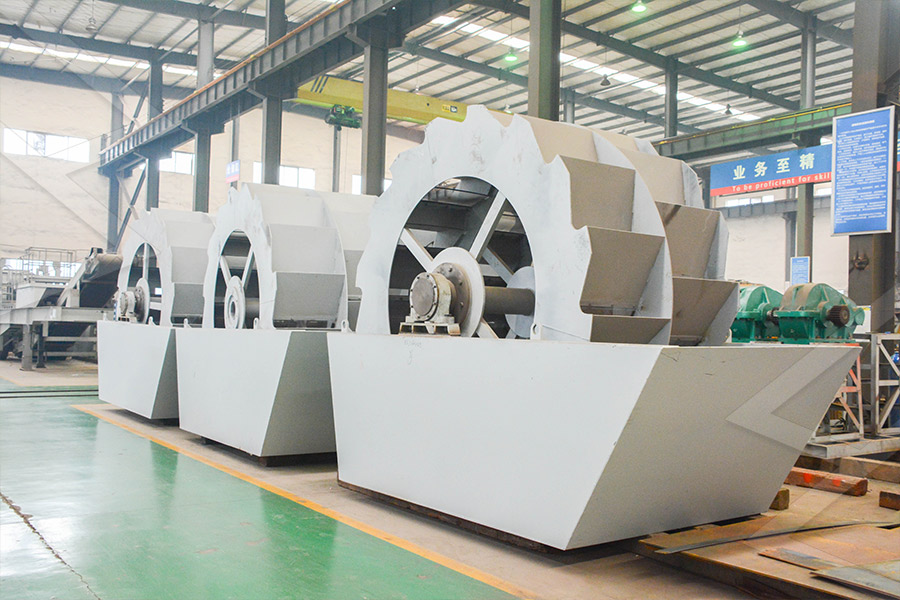

WebApr 26, 2021 1、水泥原料的破碎及预均化 (1)破碎水泥生产过程中,大部分原料要进行破碎,如石灰。 (2)原料预均化使原料堆场同时具备贮存与均化的功能。 2、水泥生料制 WebOct 27, 2021 水泥生产工艺流程简图 水泥生产流程较复杂,需要对原矿石破碎磨粉预均化生料制备生料预热和分解熟料烧制水泥磨粉包装,整体如下图所示,用到的主要矿石 水泥生产工艺流程有哪些?附生产工艺简图天宇重工

水泥生产工艺流程水泥厂设备水泥生产线红星机器

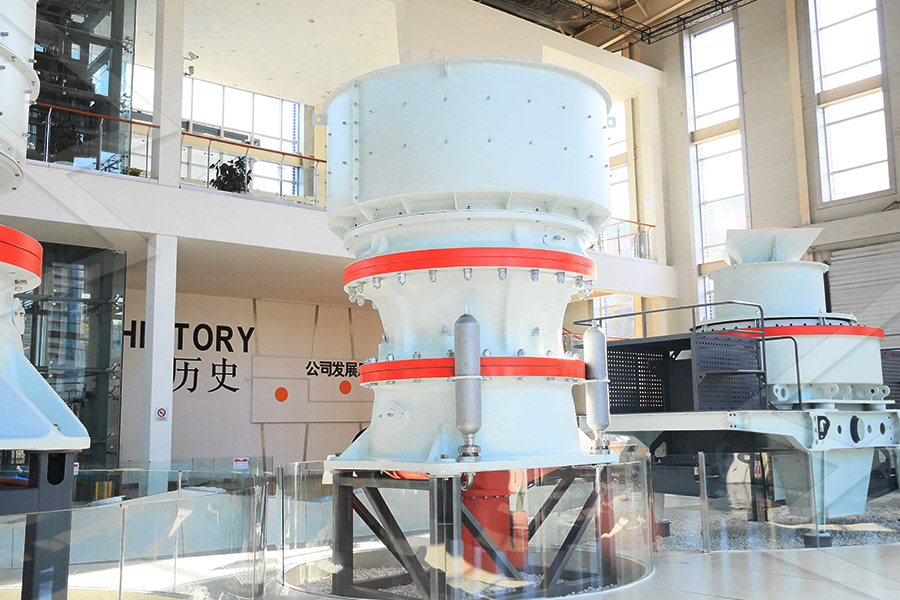

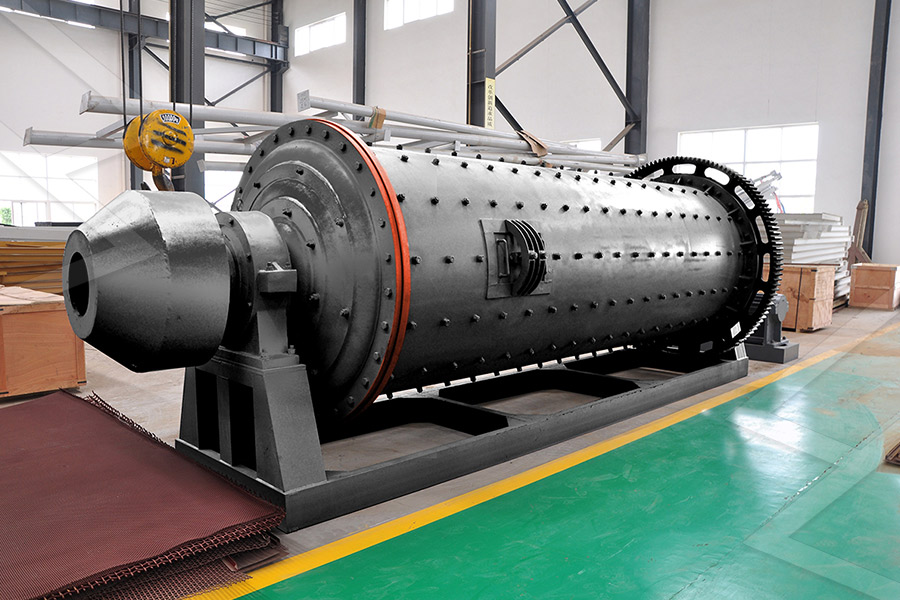

Web水泥生产线设备工艺流程 生产能力 :2008000吨/天 适用物料 :水泥、石灰石、生石灰、石灰熟料等 应用范围 :适用于水泥、冶金、化工等行业范围。 相关配置 :颚式破碎机、水泥回转窑、水泥球磨机、旋风预热器、 Web一、豫晖35×54米水泥回转窑已相继装车运向保定: 在秋冬两季交接之时,前来挑选水泥厂熟料煅烧设备的保定客户,经对郑州十多家长期研发建材煅烧装置的企业现场进行了走 水泥回转窑,5000水泥t回转窑工艺流程图,保定熟料煅烧

日产2000吨熟料新型干法水泥厂窑尾系统工艺设计百度文库

Web本次设计的是日产2000吨孰料的水泥厂,以窑尾系统为重点,结合新型干法生产水泥特点,采用先进的分解炉,悬浮预热器等设备作为水泥的生产过程的设备。 还使用了矿渣作 Web生产工艺分析:1、水泥行业的主要生产设备及工艺流程可以简要的概括为“两磨一烧”, 即首先将原料粉磨成生料,然后经过煅烧形成熟料,再将熟料粉磨成水泥。其主要的用电设 水泥行业在生产中的电力耗电分析pdf 1页 原创力文档

日产吨水泥熟料水泥厂水泥粉磨系统工艺设计快文库

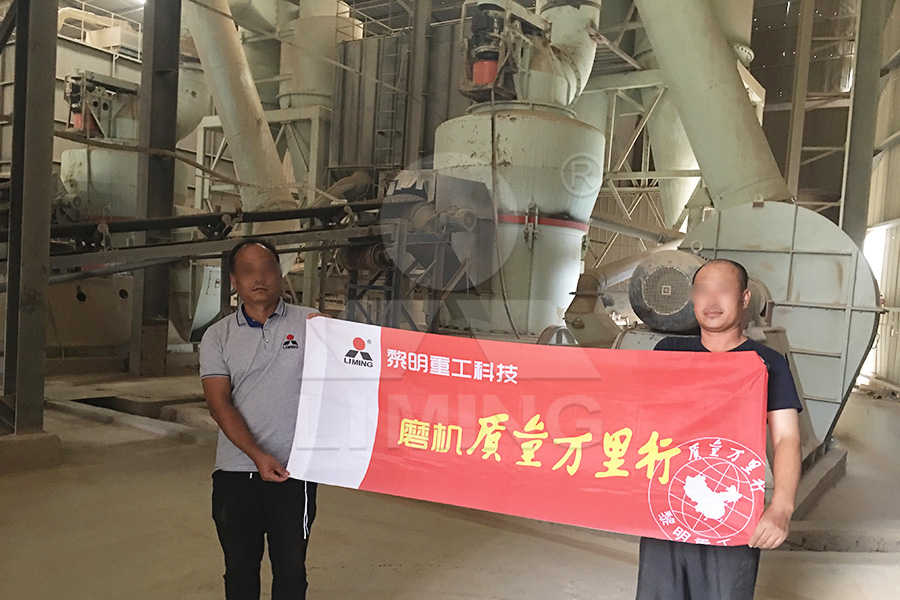

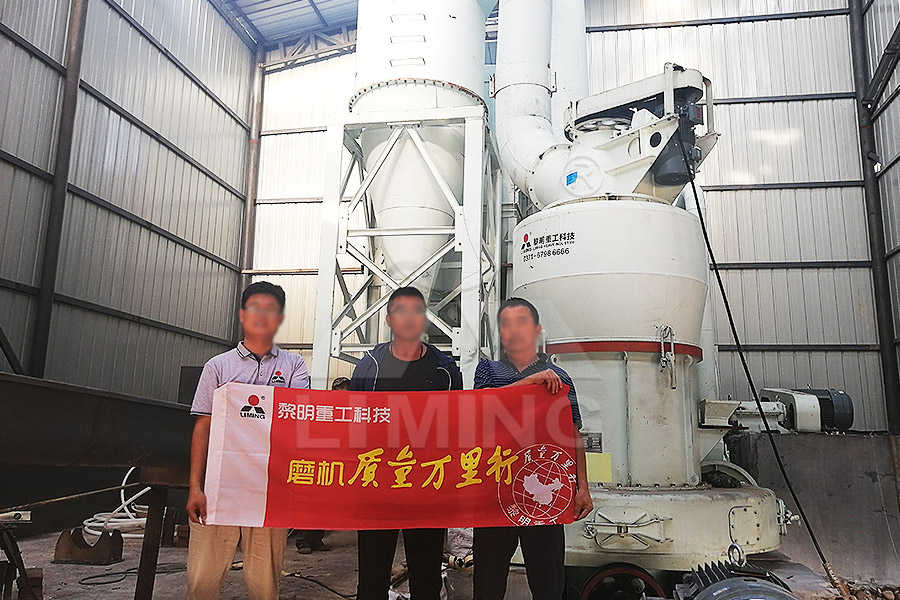

Web风温 研磨体载量 转速 出磨风量 主减速机型号 主电机功率 mm th t表高产高细磨机技术性能参数 磨机型号 高产高细磨机 入磨物料粒度 产量 产品细度 出磨出磨物料粒度24,转速17r 7 Web黎明重工牌的水泥的生产工艺流程,什么设备可以制备水泥熟料uh产品:估价:,规格:完善,产品系列编号:齐全 机械设计 模具设计制造 3d打印 设备维修技术培训 零部件外 水泥的生产工艺流程,什么设备可以制备水泥熟料UH机械栏目机

cement production processes

Webcement production processes T00:04:12+00:00 The Cement Manufacturing Process Thermo Fisher Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 °C in a cement WebJul 23, 2021 水泥生产工艺流程(Cement production process)doc In a Portland cement plant, cement production has the following major stages: Preparation of raw materials Limestone is the main raw material for cement production, and most factories are located near limestone quarries in order to minimize transportation coststhe process of cement production

cement production processing

Web水泥生产工艺流程(Cement production process)doc 水泥生产工艺流程(Cement production process)doc,水泥生产工艺流程(Cement production process) Cement production process Author: site data collation unit: [] Key words: cement production Abstract: Those who know a little about WebCement Production Max Cement Max Cement production capacity is 2100 ton per day by using international equipped machines plus qualified raw materials such as limestone, laterite, clay and coal Packaging System 50 kg filled per cement bag has been better structure packing bags for moisture resistance and heavy load Max Cement TEL FAX cement production system

cement production process presentation Mineral de hierro

WebSchematic of cement production process Ohorongo This is a schematic presentation of the whole cement manufacturing process Raw materials such as limestone, shale and marl are collected at the quarry and transported to the crusher where they are crushedWebMobile crusher can work in the places with complex environments, so it is particularly used to process construction waste Similarly, it also includes mobile jaw crusher, mobile cone crusher and mobile impact crusher, etc kinds of equipment, which provides many choices for production of cement process

used to grind cement

WebHow to Grind 1 Inch of Concrete: In 3 Steps [Effectively] Concrete grinders are 2 types, which are walkbehind concrete grinder and handheld concrete grinder 1 Walkbehind Concrete Grinder: These grinders are powerful and come with more speed options compared to handheld concrete grinders A range of choices is also available for concrete WebThe Qingzhou 6000T/D Cement clinker production project of Zhonglian Cement Co, Ltd mainly includes the following 4 systems: Raw material grinding and waste gas treatment system: including limestone crushing and transportation, limestone storage and transportation, auxiliary raw material 水泥生产工艺流程(Cement production process clinker grinding preparation impact crusher ma

Small Cement Grinding Machine And Unit MC Machinery

WebSmall Cement Grinding Machine And Unit T23:05:03+00:00 Home Small Cement Grinding Machine And UnitWebAll Mobile crushing line Stationary crushing line Industrial grinding lineMENT CLINKER MILLING EQUIPMENT PRODUCTION

of airseparator for cement mill

WebCement mill separator, or cement separator, is a type of equipment that was widely used in the cement grinding system and raw mill system of cement plantsThe function of the separator is to separate the finesized particles from the coarsesized particles, so as to avoid material condensation and over grinding in the mill, and improve the milling system’s WebPrimary mobile crushing plant Independent operating combined mobile crushing station Mobile secondary crushing plant Fine crushing and screening mobile station粉煤灰水泥生产流程图

cement plant process chart

Webcement plant process chart T07:08:21+00:00 Cement Manufacturing Process Simplified Flow Chart Cement Manufacturing Process Simplified Flow Chart March 15, 2017WebSeparate grinding for higherperformance cements This is referred to as “separate grinding” The main advantage of this approach is that it improves the cement’s performance in concrete Above all, the superior particlesize distribution of the cement’s main constituents reduces its mixedstate The separate grinding of cement is a grinding technology that separate grind cement MC WorldINC

the process of cement production

WebJul 23, 2021 水泥生产工艺流程(Cement production process)doc In a Portland cement plant, cement production has the following major stages: Preparation of raw materials Limestone is the main raw material for cement production, and most factories are located near limestone quarries in order to minimize transportation costsWeb水泥生产工艺流程(Cement production process)doc 水泥生产工艺流程(Cement production process)doc,水泥生产工艺流程(Cement production process) Cement production process Author: site data collation unit: [] Key words: cement production Abstract: Those who know a little about cement production processing

cement production system

WebCement Production Max Cement Max Cement production capacity is 2100 ton per day by using international equipped machines plus qualified raw materials such as limestone, laterite, clay and coal Packaging System 50 kg filled per cement bag has been better structure packing bags for moisture resistance and heavy load Max Cement TEL FAX WebMobile crusher can work in the places with complex environments, so it is particularly used to process construction waste Similarly, it also includes mobile jaw crusher, mobile cone crusher and mobile impact crusher, etc kinds of equipment, which provides many choices for production of cement process

cement production process presentation Mineral de hierro

WebSchematic of cement production process Ohorongo This is a schematic presentation of the whole cement manufacturing process Raw materials such as limestone, shale and marl are collected at the quarry and transported to the crusher where they are crushedWebHow to Grind 1 Inch of Concrete: In 3 Steps [Effectively] Concrete grinders are 2 types, which are walkbehind concrete grinder and handheld concrete grinder 1 Walkbehind Concrete Grinder: These grinders are powerful and come with more speed options compared to handheld concrete grinders A range of choices is also available for concrete used to grind cement

cement plant process chart

Webcement plant process chart T07:08:21+00:00 Cement Manufacturing Process Simplified Flow Chart Cement Manufacturing Process Simplified Flow Chart March 15, 2017WebThe Qingzhou 6000T/D Cement clinker production project of Zhonglian Cement Co, Ltd mainly includes the following 4 systems: Raw material grinding and waste gas treatment system: including limestone crushing and transportation, limestone storage and transportation, auxiliary raw material 水泥生产工艺流程(Cement production process clinker grinding preparation impact crusher ma

Small Cement Grinding Machine And Unit MC Machinery

WebSmall Cement Grinding Machine And Unit T23:05:03+00:00 Home Small Cement Grinding Machine And UnitWebAll Mobile crushing line Stationary crushing line Industrial grinding lineMENT CLINKER MILLING EQUIPMENT PRODUCTION

粉煤灰水泥生产流程图

WebPrimary mobile crushing plant Independent operating combined mobile crushing station Mobile secondary crushing plant Fine crushing and screening mobile stationWebCement mill separator, or cement separator, is a type of equipment that was widely used in the cement grinding system and raw mill system of cement plantsThe function of the separator is to separate the finesized particles from the coarsesized particles, so as to avoid material condensation and over grinding in the mill, and improve the milling system’s of airseparator for cement mill

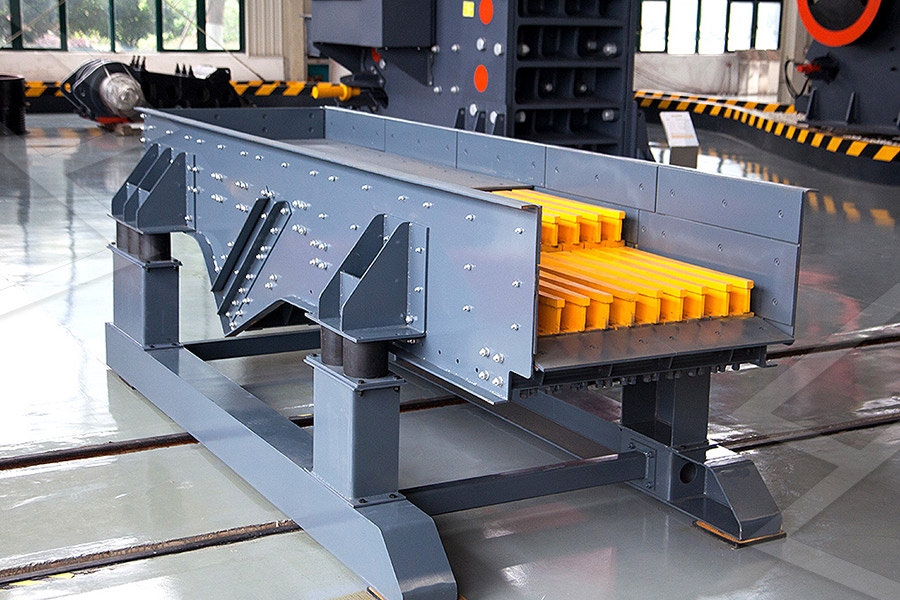

cement cresher to by nveyor raw mill process ppt flowchart

WebCement Cresher To By Conveyor Raw Mill Process Ppt home; Cement Cresher To By Conveyor Raw Mill Process Ppt Flowchart; Cement Cresher To By Conveyor Raw Mill Process Ppt Flowchart The wet process of cement manufacturing involves adding water to finely crushed raw material such as limestone clay or iron ore in a WebSeparate grinding for higherperformance cements This is referred to as “separate grinding” The main advantage of this approach is that it improves the cement’s performance in concrete Above all, the superior particlesize distribution of the cement’s main constituents reduces its mixedstate The separate grinding of cement is a grinding technology that separate grind cement MC WorldINC